About us

Changzhou Habo Trade co.,LTD is currently the only onemanufacturer specialized in the manufacturing of braided sub-pipe(textile subpipe). In 2012, Nanbo invested RMB 10 million have the annual producticapacity of 28,000, 000.00 meters. Nanbo is located in the beautiful water townof Southern Yangtze River -Changzhou city, which is near to Asian PearlShanghai in the east and near to ancient city-nanjng in the west with convenienttraffic conditions as Yangtze River, Beijing-hangzhou Canal, Beijing-shanghaiHigh-speed Railway, Shanghai-nanjing Highway and 312 National Highwaygoing through it.

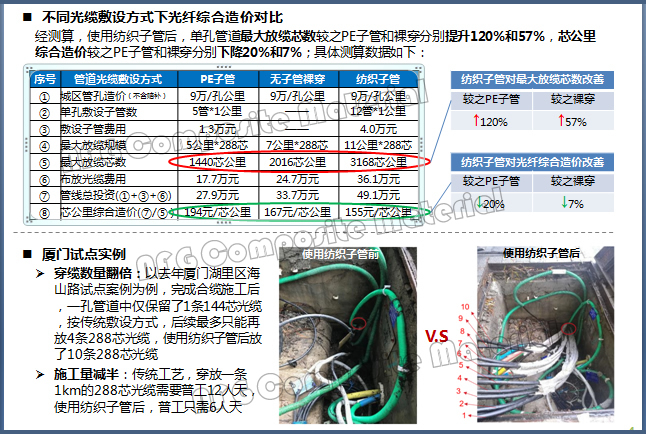

With the continuous development of network and construction of 4Gnetwork, C network base stations and FTTX, the optic cable laying increasesgreatly every year, the demand for pipeline resource increased sharply and thedemand for transmission resource increases rapidly, so the problem of shortageof network resource appears gradually, especially the rare resource like theunderground pipes are becoming less and less and the current pipeline resourcesare becoming in short supply. Under above-mentioned conditions, Changzhou Habo Trade co.,LTD independently developed the new braidedsub-pipe (textile sub-pipe)with high technology content, high quality standardand substantive human and material resource investment from 2009 to 2011 tosuccessfully develop the internationally first closed and seamless pipe.